I-Thermoformed Pulp Processing

Izixhobo zokubumba zeZhiben zibandakanya i-Swiss HSM, i-WEDM, iimatshini zokukrola, i-CMM, izixhobo zomatshini ezingama-26, ngaloo ndlela iququzelela ukufezekiswa kwe "0.1μ feed, 1μ cutting, nm-level surface effect".

I-Thermoformed Pulp Processing

U-Zhiben uphande kwaye waphuhlisa izixhobo zokubumba ezipheleleyo ezizisebenzelayo (Umatshini wePulp/oomatshini bephepha).Ngokusetyenziswa kwamandla aphantsi kunye neeyure zokusebenza ezinde njengesiseko.Sigqibe izixhobo zethu ezintsha zokubumba ipulp ezineeyure zokusebenza ezinde kakhulu ezingaqhutywa mntu.

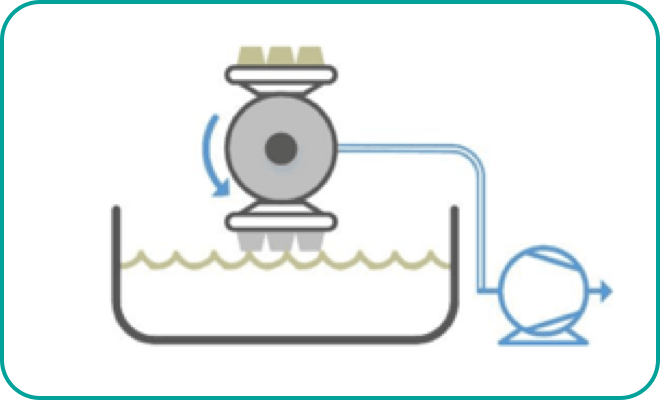

Ukuveliswa kwepulp ebunjiweyo kubandakanya ukunqunyanyiswa kwamanzi kweentsinga ezifakwe kwi-mold ekhuselekileyo.Emva koko kufakwa ivacuum kwaye i-fiber mat iqalisa ukuphuhlisa amandla athile.Amanzi anokususwa ngoxinzelelo olufakwe kwi-slurry ngokusebenzisa i-mold ehambelanayo.Emva kwesi sigaba, i-preform ebunjiweyo idla ngokufikelela kwi-50% kwi-consistency (okt iqhezu lobunzima okanye ipesenti yesiqina kudaka olunikiweyo) kwaye yomiswe ngokupheleleyo kwisingundo esishushu okanye i-oveni.

Ukusuka kuyilo lomatshini wePulp, ukuveliswa kwemveliso, ukuthengisa, ukuthengisa, inkonzo, kunye nolawulo, iZhiben ine-pulse kwinkqubo epheleleyo.Sineqondo eliphezulu lokuzithemba kuyilo lwezixhobo zoomatshini.Ngaphandle kokubamba izixhobo eziphambili, iZhiben nayo ibeke ukholo lwethu kunye nokuzithemba kumgca wethu wemveliso wokubumba.Siyahluka ekucingeni kwethu kumenzi womatshini wokubumba we-pulp.

Amanqanaba okuvelisa kwimveliso ye-Thermoformed pulp:

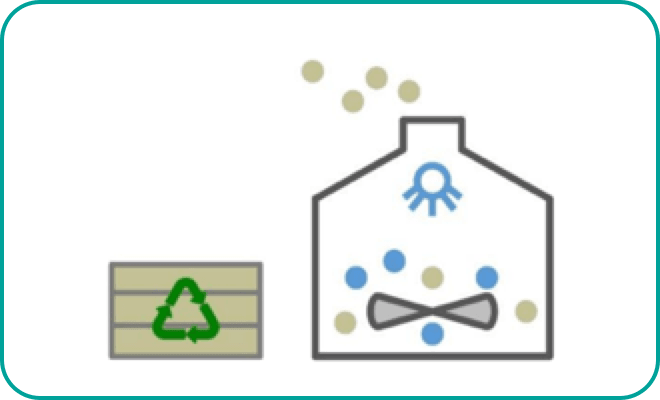

1. I-Pulpers idibanisa izinto eziluhlaza, zixube ngamanzi kwaye izinto ezingenayo i-fiber zisuswe.

2. Oomatshini batsala i-pulp kwi-mold kwaye basuse amanzi ngokufaka i-vacuum ukwenza imveliso.

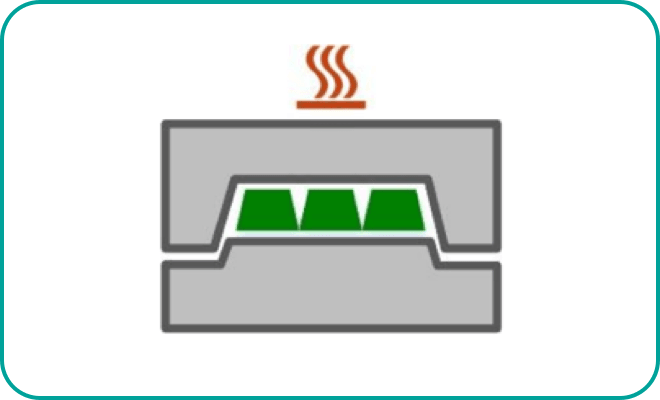

3. Inxalenye icinezelwe kwaye yomiswe ngama-halves amabini adibeneyo ahambelanayo.

4. Iindawo ezigqityiweyo zihlolwa umgangatho kwaye emva koko zipakishwe kwaye zifakwe kwipaleti.